Manufacturers construct Prefabricated Buildings outside factories and then transported to a final location for assembly. Our Prefabricated buildings in Pakistan are typically made

Providing Solutions for Construction, Management, and Restoration.

About SECO

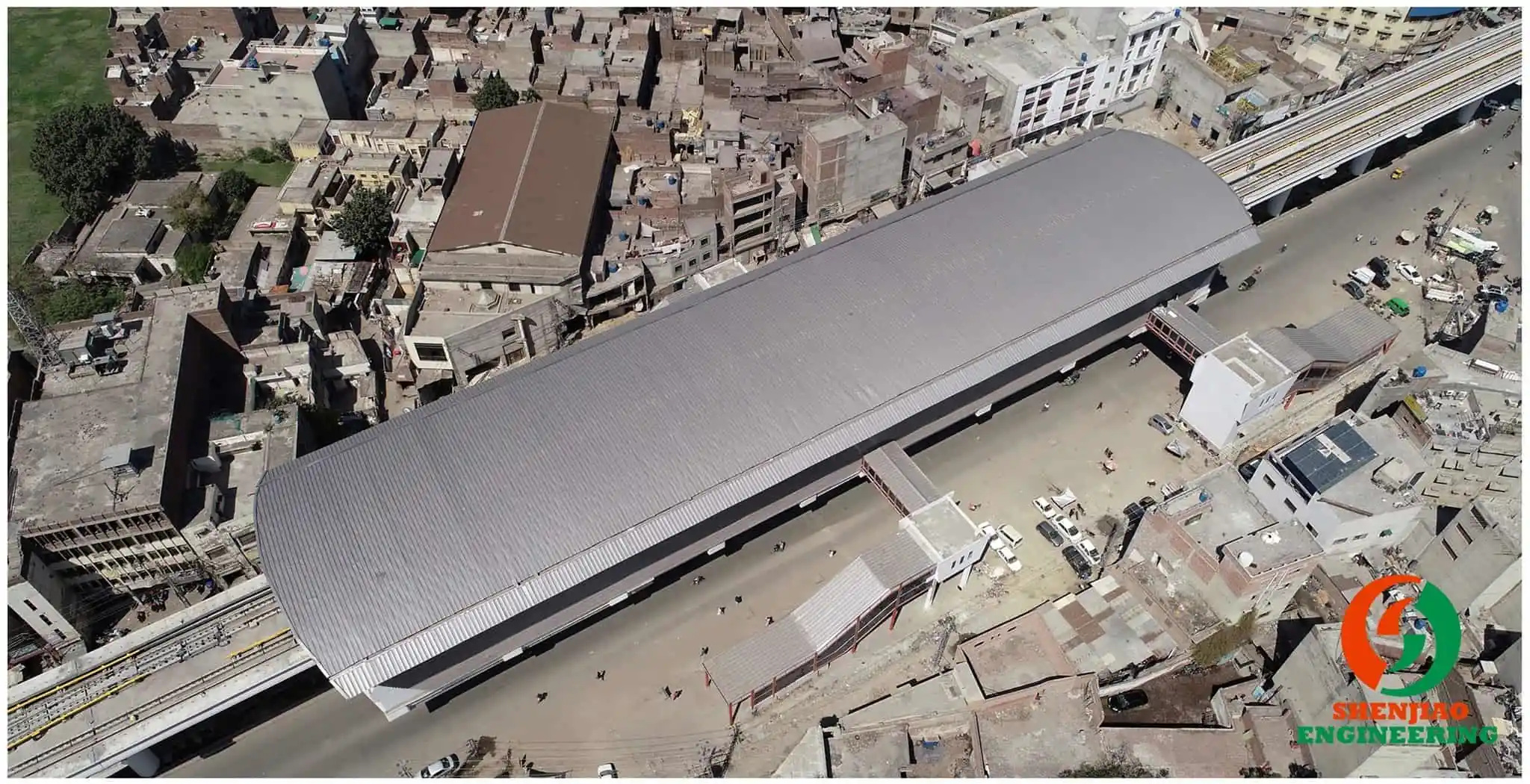

Shenjiao Engineering Company (private) LTD.” is a joint venture between China and Pakistan founded on March 20, 2017, (Company registration number: 0106917). Abbreviated SECO is located in Lahore, and the capital of Punjab which is Pakistan’s second largest city and one of the most important industrial city. But SECO covers an area of about 5 acres in area with a total investment about US $3 million. Currently, SECO is specialized in Steel Structure, Steel Template, Trolley, Hanging Basket, Concrete Batching Stations, Crane, Etc.

Explore SECO, an industry leader in various Structural Innovations that are changing how construction is done in Pakistan. With a focus on Roof Structures, SECO guarantees durability and High-Quality Craftsmanship. Our commitment is to solid Steel Structures providing sturdy frameworks that can withstand years of use. Modernizing our approach, SECO excels in the Manufacturing and Installation of Prefabricated Buildings and delivers efficiency without sacrificing quality.

With experience in Prefabricated Buildings, SECO is a leader in Pakistan with seamless integration and quick construction. As a Reputable Container House manufacturer, we are redefining living spaces by combining practicality and fashion. Our commitment to engineering excellence and customer satisfaction makes us stand out. Select SECO to provide Cutting-Edge Solutions for Roofing Construction of Steel Structures, Prefabrication, and Container Housing. We are shaping what the Construction Industry will look like in Pakistan with unshakeable confidence.

About SECO

Shenjiao Engineering Company (private) LTD.” is a joint venture between China and Pakistan founded on March 20, 2017, (Company registration number: 0106917). Abbreviated SECO is located in Lahore, and the capital of Punjab which is Pakistan’s second largest city and one of the most important industrial city. But SECO covers an area of about 50 acres in area with a total investment about US $3 million. Currently, SECO is specialized in Steel Structure, Steel Template, Trolley, Hanging Basket, Concrete Batching Stations, Crane, Etc.

Explore SECO, an industry leader in various Structural Innovations that are changing how construction is done in Pakistan. With a focus on Roof Structures, SECO guarantees durability and High-Quality Craftsmanship. Our commitment is to solid Steel Structures providing sturdy frameworks that can withstand years of use. Modernizing our approach, SECO excels in the Manufacturing and Installation of Prefabricated Buildings and delivers efficiency without sacrificing quality.

With experience in Prefabricated Buildings, SECO is a leader in Pakistan with seamless integration and quick construction. As a Reputable Container House manufacturer, we are redefining living spaces by combining practicality and fashion. Our commitment to engineering excellence and customer satisfaction makes us stand out. Select SECO to provide Cutting-Edge Solutions for Roofing Construction of Steel Structures, Prefabrication, and Container Housing. We are shaping what the Construction Industry will look like in Pakistan with unshakeable confidence.

WHAT WE DO ?

- Pre-Engineering Building

- Transmission Tower

- Custom Steel Fabrication

- Water Treatment

- Fabrication & Erection

- Pipe Line Work

- Civil Construction

- Road Safety

- Solid Waste Management

WHAT WE DO ?

- Road Marking

- Mechanical Design

- Security Products

- HVAC

- CNC Products

- Telecommunication

- Porta Cabin Works

- Galvanizing

- Container Houses

CLIENTS

Steel Structures Company:

Shenjiao Engineering Company (PVT) Ltd stands as an outstanding pioneer of excellence in construction as a Steel Structures Company in Pakistan. We Specialize In Pre-Engineering Steel Structure. We offer Solid Steel Structures that are superior to the industry’s standards. Our experience extends to Prefabricated Buildings Manufacturing and Installation, offering innovative and durable solutions explicitly adapted to the Pakistani landscape. With the most Cutting Edge Technology and a focus on high-end quality, we can redefine the possibilities of architecture. As a reputable Container House Manufacturer in Pakistan, We offer a variety of Affordable, Sustainable, and Cost-Effective Housing Solutions. Shenjiao Engineering is dedicated to creating how construction will be shortly by ensuring Quality in Construction, Long-Term Durability, and Speedy Construction Delivery. Improve your building experience by using our extensive assortment of services. We set new standards in the field of structures made from steel in Pakistan.

Steel Structure Company in Pakistan has different features such as:

Shenjiao Engineering Company in Pakistan are Highly Recommended for large and heavy structures befit to all industrial buildings.

Steel Structures mostly are cost effective as compared to other options like timber or concrete etc.

Structural Steel in Pakistan is not only lightweight but also stronger as compared to concrete or wood.

A container house is a residence made from Steel Shipping Containers. This large container is used that transport goods. We can use these containers as separate Structures, Houses, and Or Personal Offices or merge various containers to produce a different inhabitant level. Container Houses are one of the most Fixed Storage Resources you will come athwart. However, if a person changes the container into a house, they may times gash away metal and change the Structure of the Container, which does lessen its security value either.

One of the most considerable encouragement and benefit for all those assumptions about Container Homes is that they are inexpensive compared to the other traditional homes and also a safe time. It is easy to distinguish between a Container House Design and Fast Construction. Container Homes’ Price is less than Traditional Homes’ because their scrap value is reused. These houses are more durable and easy to mobility. From a structural point of view, Container House In Pakistan are made from heavy industrial materials, making them very durable and incompetent to combat grateful onshore weather conditions and environmentally friendly.

Design Considerations for Roof Structures

It generally consists of a system of structural members designed to support the roof build-up. It comprises rafters and consort, which are beams that form the shape of the roof and support overlay or next layer. Sewerage features are also based on the Roof Structure Phase. These features, like the shape of the roof, laid out and slop, are essential because they allow water to roll off the roof. The Most Durable Design of the Roofing is a Metal Hip Roof. There are two types of Roofing Structures pitched and flat Roof Structures.

Residential or Commercial Buildings commonly have pitched roofs. Pitched roofs are a type of roof that has an inclined surface. Many pitched roofs can be built using unusual materials, including shingles, metal, and tile. Flat Roof Structures commonly comprise a supporting structure, a vapor barrier, insulation, waterproofing, and adequate ventilation. The supporting structure is commonly a double-T slab. Flat Roofing Structure in Pakistan are usually designed with a pitch of 10 degrees or less.

Durability and Quality of Prefabricated Buildings

Prefabricated Construction Buildings element is built offsite and assembled onsite, is known as prefabrication. When the building element is complete, companies move to the final site. When the setup is complete, the Structure Company Transfer to its New Owners. Its most founded worker in construction and civil engineering When Prefabricated Tangible and steel components are used throughout the construction according to plan. Prefabricated tangible and steel components are used throughout the construction according to plan. Durability and Quality of Prefabricated In Actuality Manner, they can be changed easily according to the building’s final design.

The Prefabricated Buildings in Pakistan costs less because the building can be developed half offsite and assembled onsite compared to the other building materials, which are less costly. These buildings move energetically and save time. Prefabricated Methods provide many benefits, from outstanding durability and guaranteed quality to lower costs, higher green credentials, and saving time. This project is primarily for a sizeable civil building affected by calamities changes. In the prefabricated method of disposal of waste, costs are also reduced. Most of the disposed waste is recycled in the factory.